Galvatec | Fabrication & Galvanizing Technologies

Email Support

[email protected]

Call Us

+966 581803323

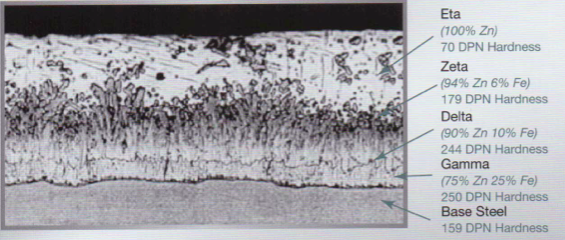

Hot Dip Galvanizing (HDG) is the best way to protect steel from corrosion since its lowest initial cost, durability, longevity, availability, versatility, sustainability, and even good appearance and finish. HDG is the process of immersing fabricated steel or iron into a kettle (bath) of molten zinc. When in the kettle, iron in the steel metallurgical reacts with the zinc to form a tightly bonded alloy coating. During the reaction in the kettle, the zinc interacts with the iron in the steel to form a series of zinc-iron alloy layers. A cross section of the galvanized steel coating shows a typical microstructure comprising of three alloy layers in addition to a layer of pure metallic zinc. So even when the first layer (ETA) is scratched, the steel is still protected by another three hard layers:

Hard, Tough & Adherent Coating

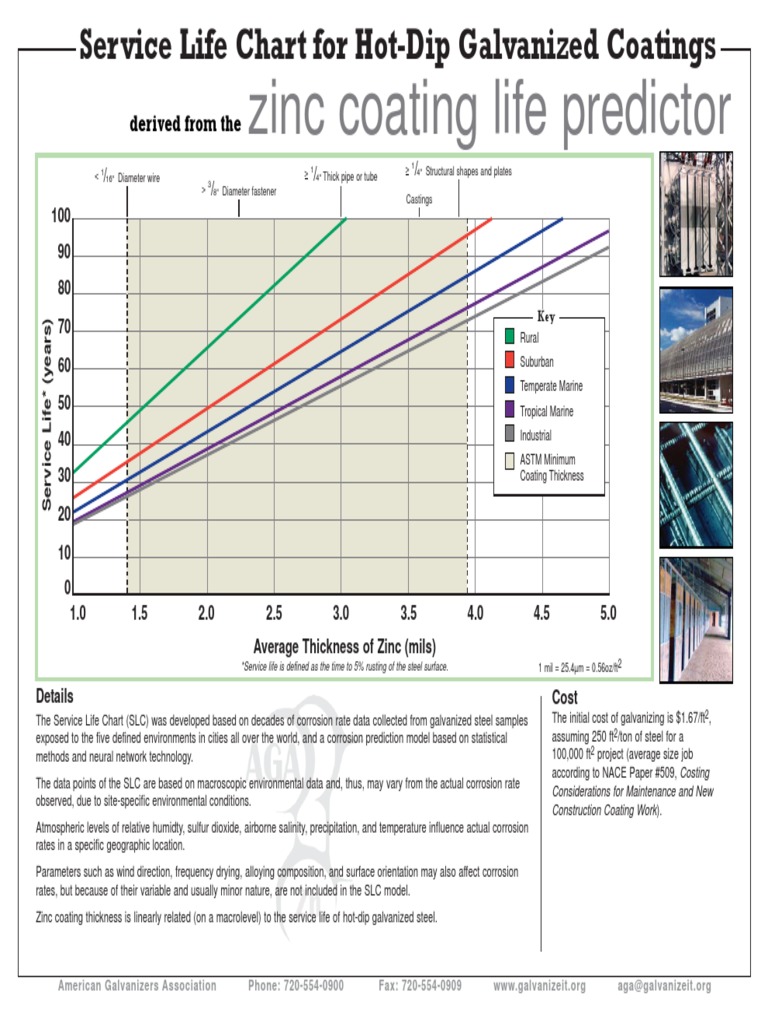

The American Society for Testing Materials (ASTM) sets the specifications required for zinc thickness based on size and use of the products. We take pride in our ability to furnish a quality zinc coating to meet your specifications. It is our desire to always meet the commitments to all our customers.

We work hard at GALVATEC to meet your scheduling requirements. Each job is scheduled based as and when the material is received for works. Each job is scheduled based on when the meterial is received at works.

CONTACT US