Galvatec | Fabrication & Galvanizing Technologies

Email Support

[email protected]

Call Us

+966 581803323

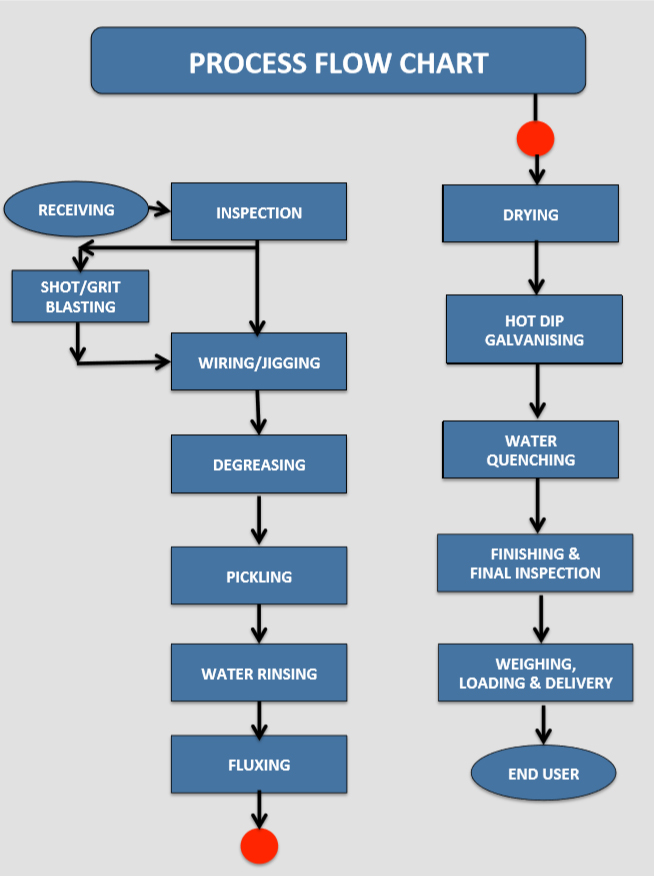

The galvanizing process consists of three basic elements: surface preparation, galvanizing, and inspection. The inspection of Hot-Dip Galvanized steel is simple and quick. The two properties of the Hot-Dip Galvanized coating most closely scrutinized are coating thickness and appearance/ surface condition. A variety of simple physical tests can be performed to determine thickness, uniformity, adherence, and appearance. Products are galvanized according to long established, accepted, and approved standards. A variety of simple physical and laboratory tests are performed to determine the aforementioned parameters as per ASTM/ BS Standard requirements/ specific customer requirements.

Work instructions are given for cleaning and rectification wherever necessary: Filing method or grinding by abrasive wheel is practiced to remove excess zinc. Minor repairs are done by applying rich zinc paint with a brush. Products are galvanized according to approved standards of ASTM. These standards cover everything from the minimum required coating thickness for various galvanized items to the composition of the zinc metal in the process.

Types of Inspection:

Various inspection types are used to verify the necessary specifications for the galvanized product are met. These techniques for each test method are specified in ASTM A 123/A 123M, depending upon the type of product being inspected. The most common inspections range from a simple visual inspection to a more sophisticated test to determine embrittlement or adhesion.

We work hard at GALVATEC to meet your scheduling requirements. Each job is scheduled based as and when the material is received for works. Each job is scheduled based on when the meterial is received at works.

CONTACT US